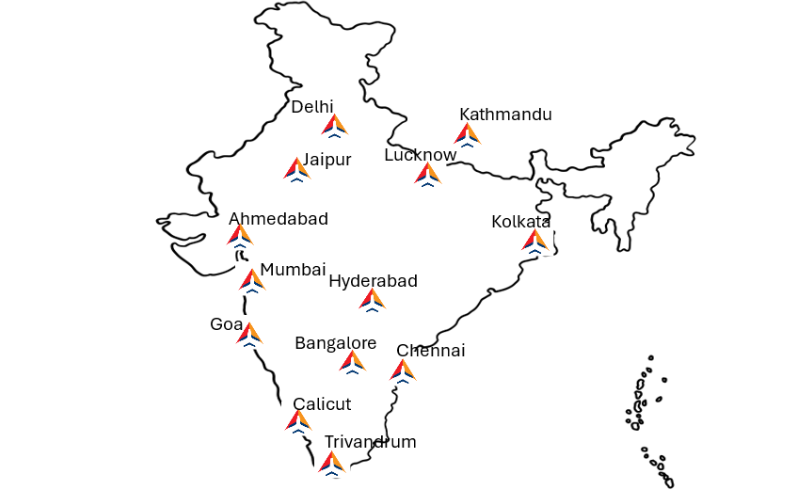

Heavy Maintenance, End Of Lease Services, Recovery of the Aircraft, Full Repainting of the Aircraft, NDT Services onsite as well as offsite at other stations including International Locations etc.

Boeing 737 NG and MAX

Boeing 737 NG and MAX Airbus A320 ( CEO and NEO)

Airbus A320 ( CEO and NEO) B737 NG Family

B737 NG Family A320 Family

A320 Family Q400

Q400 ATR 42/72

ATR 42/72

GAT can perform Scheduled Heavy Maintenance, Major Structural Repairs, End Of Lease Checks/Redelivery Check, Picke Fork Replacement, Fuselage Frame 16 Replacement, Fuselage Nose Section Lower Skin Replacement, Aircraft Painting including Complex Livery Painting. The works required for accomplishment of Service Bulletins (SBs) and Airworthiness Directives (ADs) are also performed.

ELCH Bond testing and Digital Tap Testing

ELCH Bond testing and Digital Tap Testing Fluorescent Penetrant Inspection

Fluorescent Penetrant Inspection Magnetic Particle Inspection

Magnetic Particle Inspection Eddy Current

Eddy Current Ultrasonic

Ultrasonic Radiography

Radiography Thermography

ThermographyThe facility is equipped with clean room and suitable for cold and hot bonding repairs on composite aircraft structures/ parts and cabin items. The repairs on thrust reversers, floor board, engine cowling, flight control and other parts are also performed.

The shop has the capability to perform I.R.A.N (Inspect and Repair as Necessary), rectification and refurbishment of aircraft seats including plastics parts, structural parts, cushions, meal tables etc..

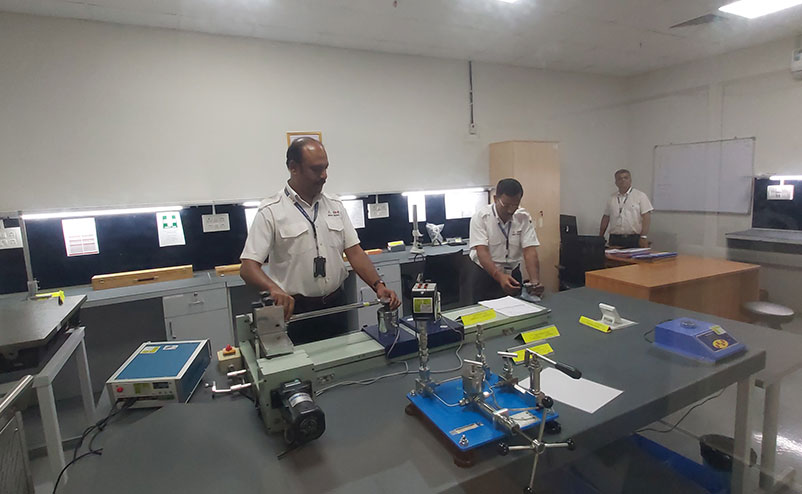

Calibration lab is equipped to underake the calibration of tools and equipment

The shop has been providing structural and composite repair support for EOL checks and major checks like Skin replacements, Frame replacements etc.

Can perform maintenance of Heat Exchangers of Airbus A320 Boeing737 and ATR72

GAT has a fully equipped paint hangar can accommodate one narrow body aircraft. This hangar is equipped with extraction system, hangar door and docks for painting of complete aircraft, with rub down & stripping method as per the customer requirement.

Ample of Parking space in front of the hangars to park Aircrafts for short and long term aircraft perservation.

GMR Aero Technic (GAT) has recently signed an agreement with Spirit AeroSystems to be the Spirit Authorized Repair Center in India for its Boeing and other aircrafts.

As per this agreement, GMR Aero Technic will provide repair services of nacelles, radomes, and flight control surfaces for all narrow bodies, including Boeing’s 737 NG and MAX aircraft.

This strategic partnership between GMR Aero Technic and Spirit AeroSystems provides a one-stop solution to GAT’s customers by establishing repair capabilities for nacelles and radomes jointly in India. This partnership reaffirms GAT’s commitment to provide world-class MRO services and further contribute to the Make in India initiative by providing value-added services to its customers in this part of the world.

GMR Aero Technic (GAT), the MRO (Maintenance, Repair and Overhaul) division of GMR Air Cargo and Aerospace Engineering Ltd. (GACAEL), has been awarded a contract to convert 737-800 passenger aircraft into a 737-800BCF configuration. GMR Aero Technic is the first Boeing Converted Freighter (BCF) partner to be located in India. The partnership will support conversions of both domestic and foreign aircraft.